I had been thinking of getting a headset for quite some time. I had always known it would have made contesting much easier. However, when I began working full duplex through satellites, a good headset was no longer an option but a necessity. A quick search through the various ham radio catalogs and on-line vendors revealed such a headset cost considerably more than I was willing to spend. EBAY to the rescue! I found a TELEX PH-10 headset listed on Ebay. This unit appeared to be in unused condition, had a noise-cancelling boom mic, and headphones which offered over 20 dB of OSHA-approved hearing protection! All I needed was some kind of interface to make it work with my Kenwood TS-2000X. 2 days and $17 later, the headset was mine. As I waited for my purchase to complete its 4 day ride in the big brown truck, I began designing the interface. The first step involved visiting the TELEX web site and examining the TELEX PH-10 SPECIFICATION SHEET.

Consulting the Telex and Kenwood manuals, it became clear that the electrical portion of the interface itself would be a piece of cake involving only a few components. The physical design was another story. The headset's single cable would need to connect to both the MIC and HEADPHONE jacks on the radio's front panel, requiring some sort of splice in the cable. Since the headset had no PTT function, I needed to incorporate a PTT switch into the interface. And finally, I wanted to be able to use the headset with other radios, which precluded permanently hard-wiring it to TS-2000 style connectors.

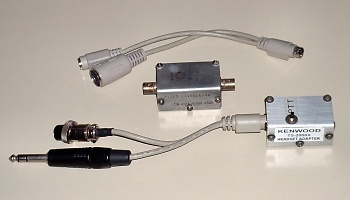

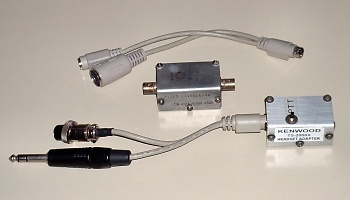

After a few minutes of rumaging through my junk box, I found a handful of parts which I felt would do the trick. In fact, the only components I needed to purchase were the miniature 3 pin XLR connectors for the headset cable! The interface was assembled from a military surplus aluminum enclosure, and old PS-2 style mouse jack, and a PS-2 mouse/keyboard splitter cable! I removed the BNC connectors from the enclosure which had at one time housed a toasted 10dB attenuator. A 3 pin female mini XLR connector was mounted in one hole, and a female PS-2 mouse connector (saved from an old 486 motherboard installation kit) was mounted in the other hole. I drilled a 3rd hole in the side of the enclosure for an SPST momentary push button PTT switch. The photo at left shows the parts in both their original and modified form.

Ohming out the PS-2 Y cable revealed that not all pins on both pigtails were wired in parallel. Each of the connectors had unused pins. Carefully drawing out a wiring diagram of the Y cable quickly revealed that only 1 pigtail had enough conductors for the mic connection, designating the other pigtail for use with the headphone jack. The existing mouse and keyboard connectors were cut off and replaced with the appropriate headphone and mic connectors. Finally, a miniature 3 pin male XLR connector was soldered to the headset cable. Full details can be seen by viewing the SCHEMATIC DIAGRAM.

Having successfully completed the TELEX headset interface for the Kenwood TS-2000X, I moved on to designing one for my Kenwood TH-F6A HT. The electrical portion of the interface was even simpler, as can be seen in the SCHEMATIC DIAGRAM. The most difficult part of the design, however, was the cable between the interface and the HT. It had to be long enough to allow some flexibility in placement when being worn, yet not so long as to cause dangerous tripping or entanglement hazards. The biggest problem was in the stereo mini and sub-mini plugs needed for the HT. Soldering such small plugs onto a home-made cable would surely result in long term durability issues when used in the field. And the required splice to join these 2 connectors into a single cable would also be subjected to failure inducing strain.

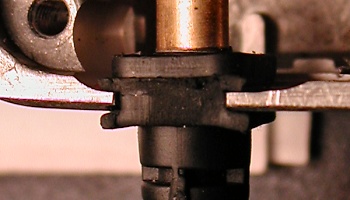

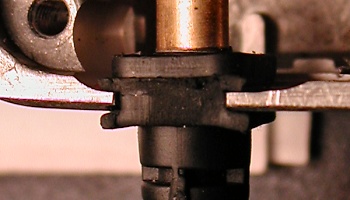

Then the solution hit me! At the next hamfest I attended, I purchased 2 generic, Chinese-made "Kenwood-compatible" speaker-mics for $11 each. The first one would be used for it's intended purpose. The second one would become a parts donor! After removing the coiled cord from the speaker mic, I discovered I could also make use of its molded-in strain relief. I drilled a hole next to the top edge of the interface enclosure, and using a miniature square file, proceded to shape the hole into a square slot which would accept the strain relief. Since the enclosure wall was thicker than the plastic speaker-mic housing, I also had to mill the wall around the strain relief slot down to the proper thickness. Once finished, the strain relief slid into place easily, with the enclosure cover keeping it locked in place. The photo at left shows a close-up of the strain relief mounted in the milled opening.

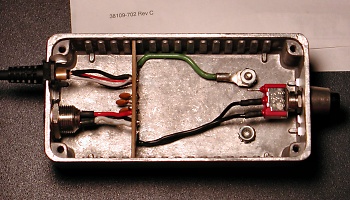

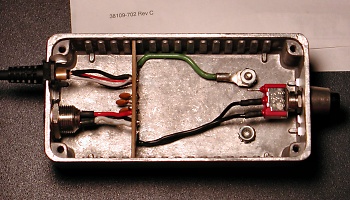

An aluminum Bud enlosure was chosen to house the HT interface due to it's durability as well as RFI shielding qualities. The enclosure was intentionally sized a little on the large size, as I had considered the possibly of building a small audio interface into it someday. This would allow using a laptop computer with the HT in the field for various digital modes such as APRS, SSTV, or PSK31. A small perf board connects the speaker-mic cable to the 3 pin mini XLR headset connector, and allows for easy mounting of the RF bypass capacitors. Although bypass capacitors were not required in the TS-2000X interface, I felt it wise to include them here, as the interface and headset would be used in close proximity to the RF fields generated by the HT's 5 watt VHF/UHF transmitter and antenna.

A surplus belt clip, salvaged from an old broken Icom W2A HT was mounted on the rear of the interface enclosure. The parts layout is such that when clipped to the belt, the PTT switch faces up on the top of the enclosure, while all cabling enters and exits from the bottom. This makes it easy to activate the PTT with the thumb, while offering some protection against accidentally keying the transmitter from leaning on something. The cable and connector locations along the bottom of the cabinet help prevent rain water from entering the interface or the connectors, while minimizing flexing and strain due to the effects of gravity.